Flexoflash is a high-quality lead free flashing solution suitable for all typical roof flashing installations. Made in Europe, Flexoflash is accompanied by a comprehensive 20-year warranty.

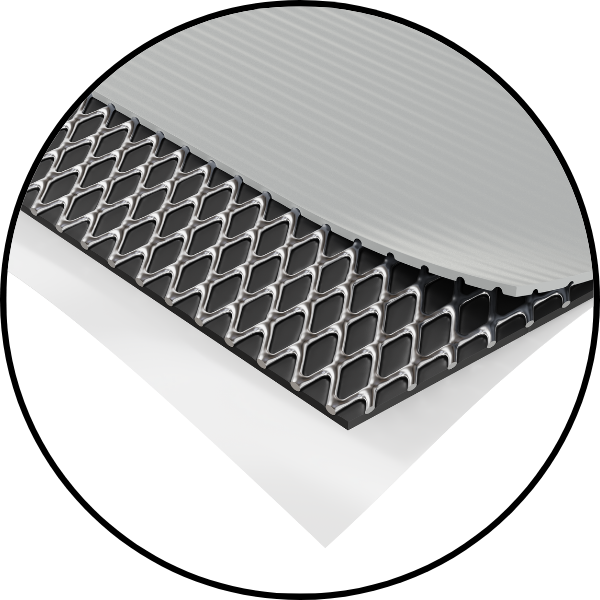

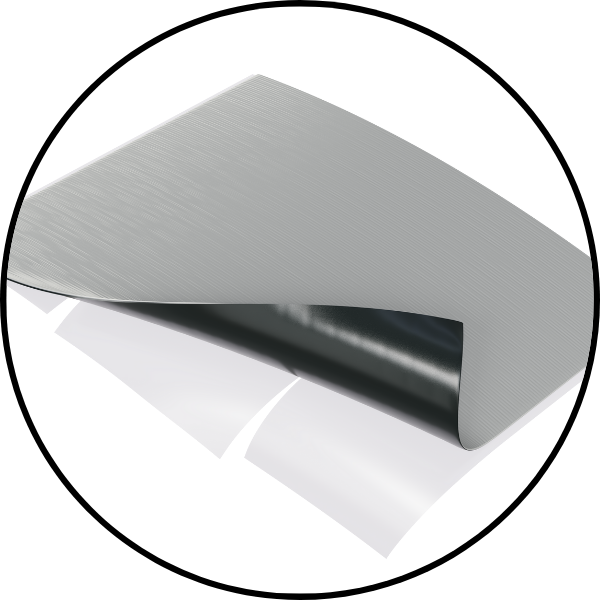

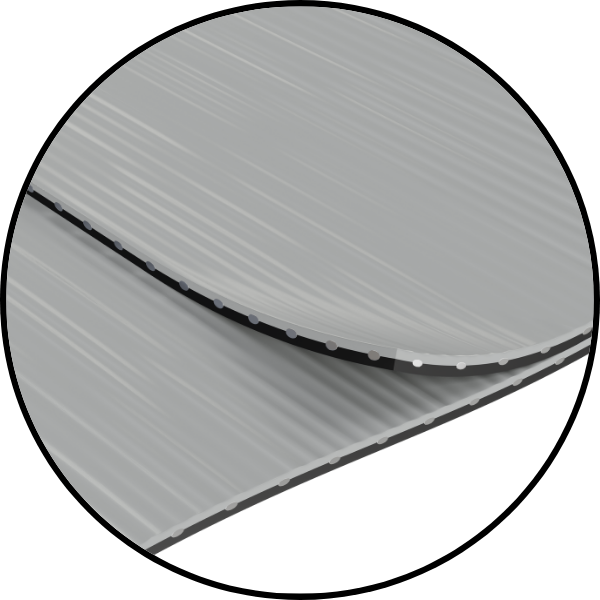

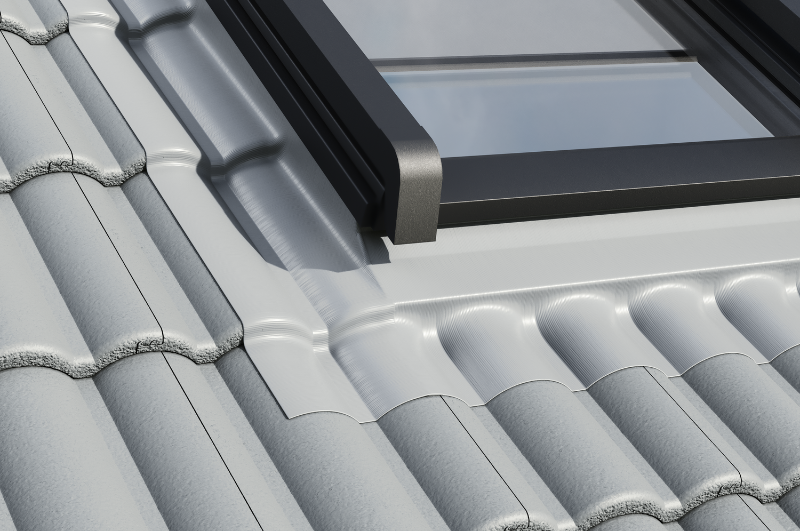

Flexoflash is a premium lead free roof flashing. Crafted from an extruded Polymer rubber known as Polyisobuthylene (PIB), Flexoflash possesses a unique self-fusing capability when overlapped. This allows Flexoflash to form a continuous watertight and airtight seal. Internally, Flexoflash includes an aluminium mesh that provides rigidity and a lasting memory when dressed to the roof surface. Flexoflash is backed by a fully self-adhesive butyl layer, ensuring a completely watertight seal. With a three-dimensional stretch capacity (up to 80% in length and 30% in width), Flexoflash is engineered to replace traditional lead flashing across all its traditional applications and seamlessly integrates with any roofing material for a smooth finish.

BEST FOR – New build applications such as abutments, step-flashing, chimneys and Dutch Gables.